News

Super New Chip Launch | High-Precision Gas Mixing System 3.0 Newly Released

2025-08-27

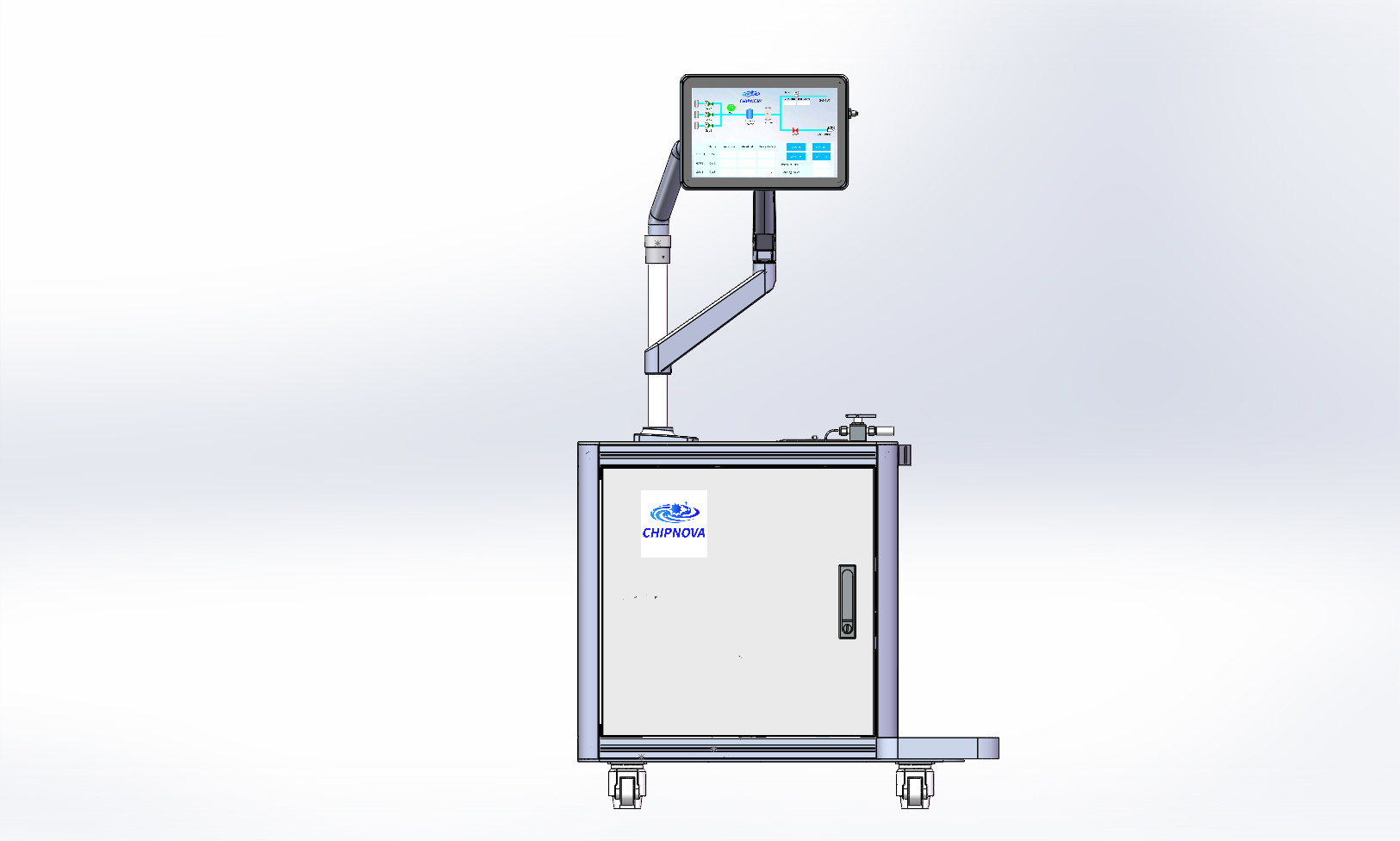

The gas mixing system is an important supporting device for the in-situ gas system of transmission electron microscopes and a crucial factor for the success of in-situ gas experiments. The gases used in in-situ experiments must have the following elements: 1. Gas purity; 2. Accuracy of gas mixing ratio; 3. Safety.

Product Features

1. Gas purity: From the initial design, the ChaoXinXin gas mixing system places great emphasis on gas purity. To achieve this, we have integrated two impurity removal modules.

① Heating module: Accelerates the volatilization of trace impurities on the gas pipeline walls, then removes impurities through gas purging;

② Freezing module: Removes trace organic carbon and other impurities in the gas by ultra-low temperatures below -170°C.

Through the close cooperation of heating and cooling, high gas purity is ensured. At the same time, we optimized the gas purging efficiency, significantly reducing the purging time while ensuring gas purity, thus improving efficiency.

2. Accuracy of gas mixing ratio: ChaoXinXin equips the gas mixing system with high-precision gas flow meters. Customers only need to set the ratio, and the system automatically intakes and mixes gases. After continuous 24-hour reliability testing, the gas mixing ratio remains stable without fluctuations.

3. Safety: If a gas leak occurs during in-situ gas experiments, it can cause gas to enter the microscope chamber and damage the microscope. The ChaoXinXin gas mixing system is equipped not only with ultra-high precision gas flow meters to accurately control gas flow rates but also integrates highly sensitive gas pressure sensors to monitor gas pressure. In the event of a gas leak, the system immediately cuts off the gas supply and prevents backflow of external air. These features provide redundant safety designs for in-situ gas experiments.

Optimization and Upgrades

Although achieving the above three points is already challenging for a high-precision gas mixing system, for us, this is far from cool enough. Therefore, we have made the following optimization upgrades to the high-precision gas mixing system:

1. Optimized humidification function: For specific in-situ gas experiments, humidification of the gas is often required. Therefore, we optimized the humidification module to be flexible and controllable, allowing customers to configure it independently.

2, Added gas pressure regulation function : For specific in-situ gas experiments, it is often necessary to regulate the gas pressure in the reaction chamber. ChaoXinXin has designed a reaction chamber gas pressure regulation module , which can adjust the gas pressure in the reaction chamber ( <1 atm) to meet different experimental needs of customers.

ChaoXinXin Technology adheres to the customer-first philosophy and continuously upgrades and iterates its products. The brand-new launch of the high-precision gas mixing system 3.0 is our practice of this philosophy and our persistent pursuit of technology. We always hope that customers can not only use the in-situ system well but also that the in-situ system becomes increasingly user-friendly. Welcome all customers to purchase!

欢迎各位客户选购!