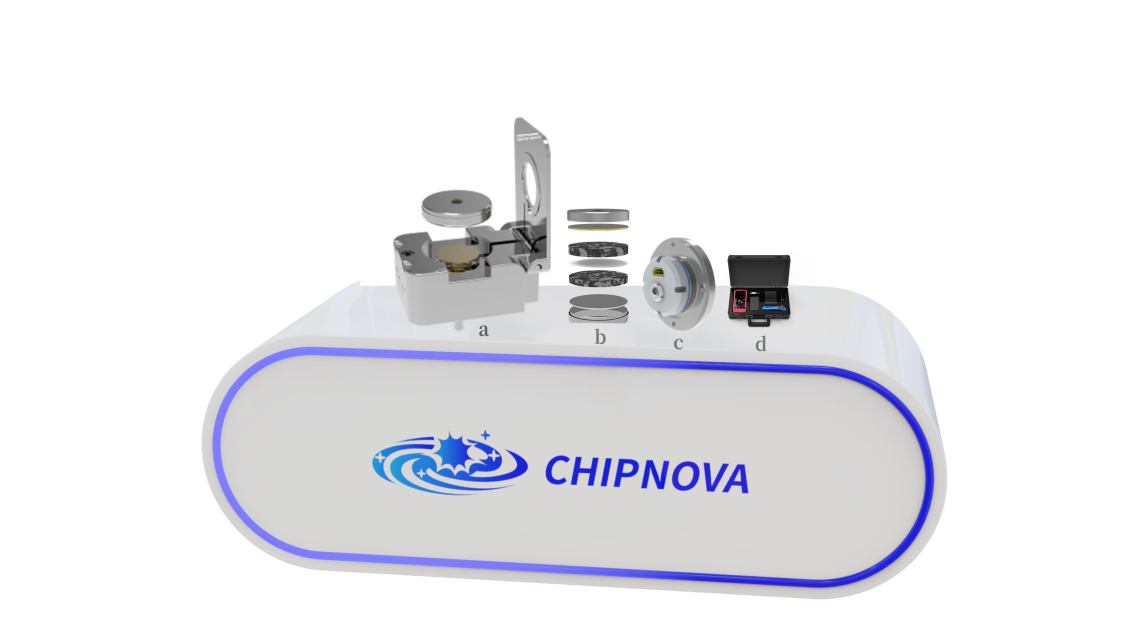

Working condition battery electron microscopy system

Product Features

- Product composition

- Unique Advantages

- Functional Parameters

- Application

-

a.SEM button type battery electrochemical table b.Button type battery composition c.Flange d.Accessory kit -

Design advantages

Unique MEMS chip special structural design, high-quality imaging

The thinnest thickness of silicon nitride film can reach 10nm, and the liquid phase environment can achieve nanometer level resolution.

Ultra high temperature coating technology, the silicon nitride film in the chip window area has the advantages of high temperature resistance, low stress, corrosion resistance, and radiation resistance.

Real-time feedback

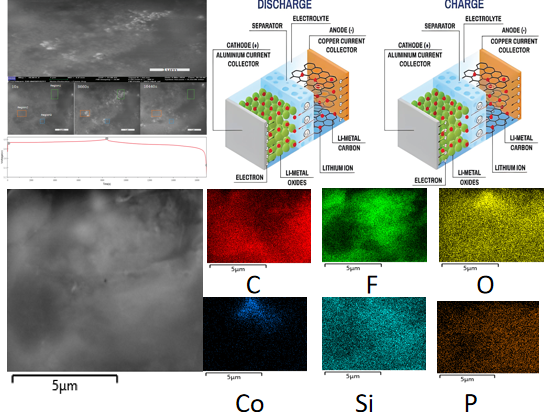

Realize dynamic observation of the charging and discharging process of the battery under working conditions.

Combined with the application of energy dispersive spectroscopy (EDS), in-depth material interface analysis can be carried out by assisting in real-time observation of changes in the internal components of the battery.

Promote the understanding of the internal chemical reaction mechanism of batteries and provide scientific basis for the design of energy storage solutions.

-

Basic parameters

Platform material

High strength titanium alloy

Silicon nitride film

10nm、20nm、50nm(Customizable)

Electrochemistry

Electrochemical system

Three electrode system(WE/CE/RE)+Electrochemical workstation

Electrode material

Au、Pt、Ti、C customizable

Current range

PA-A , Minimum detection current 1PA

Voltage range

±10V

Way of working

Electrochemical impedance spectroscopy, cyclic voltammetry, chronoamperometry, and charge discharge curve analysis

-

Chemical reaction process in the microsystem of button type battery operating conditions.

Real time SEM images and EDS analysis of the environmental interface of lithium cobalt oxide during charging and discharging processes.

Related Products